Application

For large packaging volumes.

For products with various heights and weights

Features

Automatic packaging without defined order

Advantages

Constant packaging speed.

Precise process cost estimation.

The amount of packaging types is reduced to a few sizes

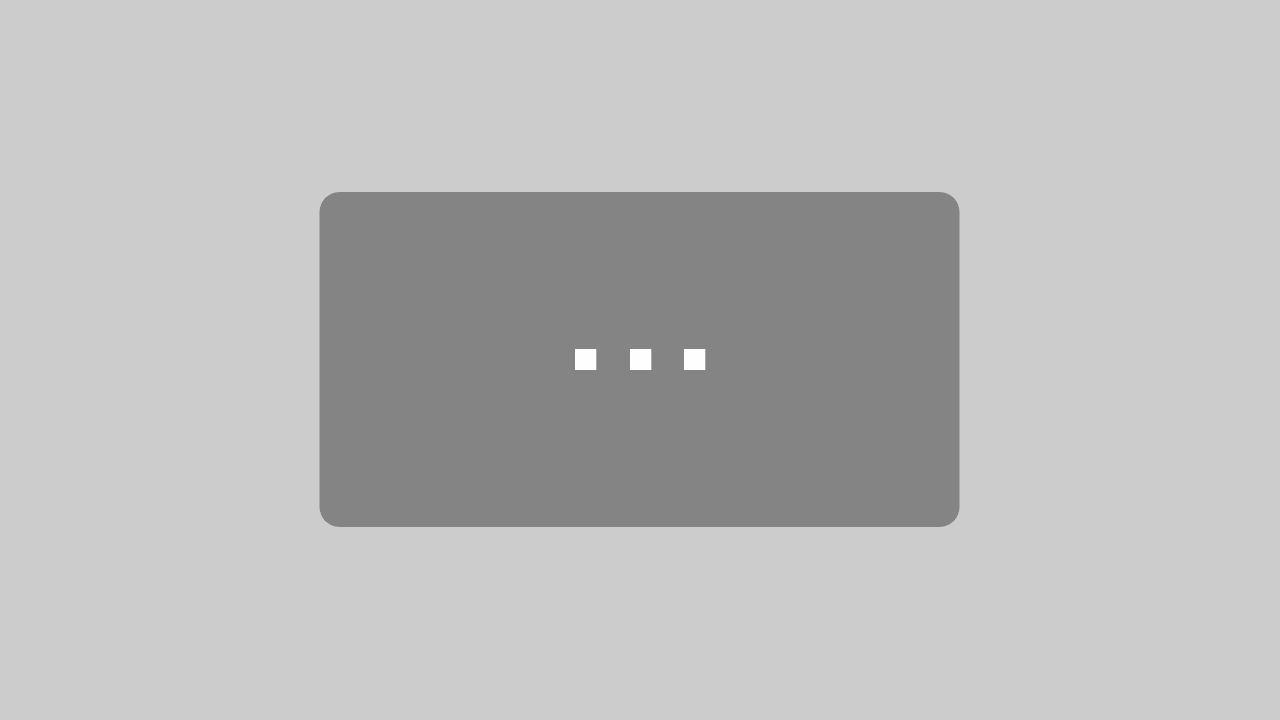

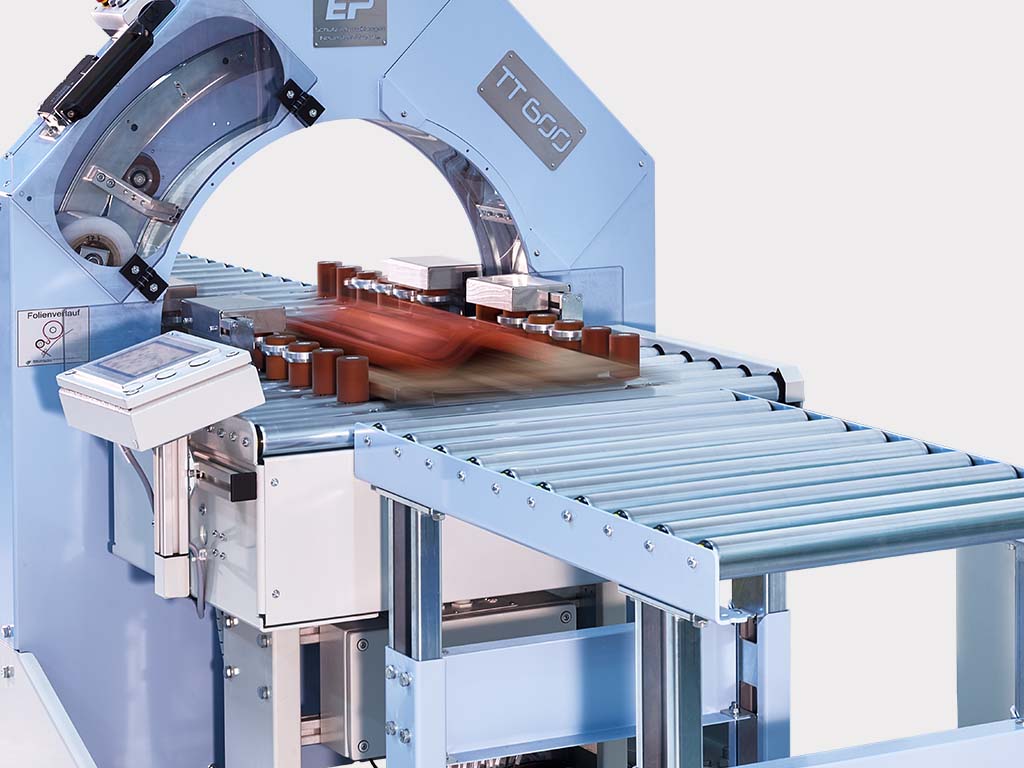

Emba-TrayTec® – The automatic packaging solution

The technique

The product is placed onto a defined tray. The shape, the dimensions or the heights of the product do not matter. The important thing is that it fits the size of the provided shipping box. The automatic feed is used to vertically wrap both – the tray and the product – with the special stretch film. The product is firmly clamped onto the corrugated board format and can be securely shipped in a box.

Product video

How does the concept work?

Our team develops the sizes you require based on your daily packaging tasks. Furthermore, the new standard program without tool costs can be used. Once the packages have been checked and found to be in perfect condition,

we‘re ready to start.

You enter into a supply contract for the quantity you require. Then, Emba-Protec will supply you with the wrapping machine, including detailed instructions. All necessary packaging components (trays, film, shipping cartons) are supplied to you on call off. You only pay a fixed set price per packaging supplied. We, of course, will assist you with any queries and wishes for modification. This is part of our customer service.

semi-automatic system

A semi-automatic system with easy handling. For small quantities and few placement options. This system allows for individual wrapping. And your products will always reach their destination safely.

hybrid version

The hybrid machine covers the gap between the semi-automatic and the fully automatic machine solution, in terms of price and technique.

fully automatic system

The fully automatic system for high throughput quantities. Up to 6 packing operations per minute are possible! Equipped with many features, e.g. automatic tray detection or a variety of different wrapping programs.